Latest News

- Hyundai E&C Accelerates Global Nuclear Expansion into the U.S. Nuclear Market

- Hyundai E&C Shifts into High Gear to Enter Nordic Large-Scale Nuclear Market

- Hyundai E&C Strengthens Korea-Japan Cooperation in Energy Transition and New Growth Businesses

- Hyundai E&C Signals Green Light for Large-Scale Nuclear Power Plant Business in Europe

- Hyundai E&C Unveils Energy-driven Growth Strategy “H-Road”

[Hyundai E&C Encyclopedia Vol. 10] 3D Printing, the 21st Century Alchemy of Innovation

Printing has long been one-dimensional, but have you ever heard of printing a house? This is 3D printing: the same “print” idea, but in three dimensions. Like alchemy turning non-metal into gold, 3D printing is seen as modern alchemy, transforming flat designs into three-dimensional shapes. Let us explore the intriguing world of 3D printing.

The Endless Realm of 3D Printing

Recently, nothing short of a miracle happened to a little boy in England. Without arms by birth, he was given a powerful Ironman arm he'd always wanted. Unlike traditional prosthetics, it is light enough to be worn by a child and can lift up to 8 kg, and most importantly, customized to fit the little boy’s body.

The remarkable advancements across various sectors are largely attributable to 3D printing technology. This is evident from the numerous reports, both within Korea and internationally, of successful transplants involving ears, noses, skulls, and other body parts, all customized through bioprinting. The scope of 3D printing is vast, with applications ranging from replicating the flavor and texture of beef using plant-based proteins to constructing houses as if by magic. For instance, last year in Georgetown, Texas, the U.S. construction company Lenner, in collaboration with the 3D printing startup ICON, built a three-bedroom, two-bathroom house in less than a week. They are now advancing to pre-sell homes in a 100-home complex. More recently, NASA announced a project to construct a building on the moon by 2040 using 3D printing.

Finding an industry that doesn't utilize 3D printing is becoming increasingly difficult, as the technology's applications continue to broaden across medicine, science, construction, art, and beyond. In fact, the global 3D printing market is expected to grow sixfold, from $18.33 billion in 2022 to $105.9 billion in 2030*.

*Source: Fortune Business Insights.

[ Children wearing 3D printed "Hero Arms", which allow them to pick up objects and write with their fingers, greatly aiding them in their daily lives. (Photo source: Open Bionics website) ]

Additive Manufacturing Principle of 3D Printing

3D printing, a pivotal concept in the Fourth Industrial Revolution, has a history extending back further than many realize. Initially developed by Hideo Kodama at the Nagoya Municipal Industrial Research Institute in Japan in 1981, this technology was patented by American engineer Charles W. Hull in 1984. However, it wasn't until the expiration of Hull's patent in 2014 that 3D printing truly began to flourish. The revolutionary aspect of what is also known as “additive manufacturing” lies in its method of creating three-dimensional objects by layering material, a stark contrast to traditional methods involving cutting, gluing, and shaping. This approach significantly reduces the cost and time required to produce individual items, leading to more economical and sophisticated manufacturing processes.

The basic principle is to analyze the object you want to print by dividing it into thin layers, like a computed tomography (CT) scan. Based on the data analyzed by 3D CAD modeling, a variety of materials such as solids and liquids can be layered on top of each other to create the output. Instead of cutting the material with a tool, materials are stacked from the bottom to the top according to the shape entered in the data, making it easy to create complex designs with atypical geometries.

The primary 3D printing methods include Fused Deposition Modeling (FDM), Stereolithography Apparatus (SLA), and Selective Laser Sintering (SLS). Unlike FDM, which uses heat-soluble materials that are drawn out like a long traditional Korean rice cake and melted bit by bit to form a shape, SLA utilizes thermosetting resins that form a cross-linked structure and harden when exposed to heat. While SLA uses a digital projector light source to spray a thin layer of photocurable plastic onto a plate, SLS uses a powdered form of the polymer and fuses it with a laser or adhesive to achieve the result.

3D Printing in the Construction Sector

3D printing is revolutionizing the traditional construction industry. The "additive manufacturing" method of layering only the necessary materials to realize the finished product is combined with cutting-edge technology to automates and accelerates construction. In particular, it is believed to be easier to realize unconventional geometries than traditional methods.

Moreover, concrete, a core material in construction, is playing an increasingly important role in construction sites thanks to 3D printing technology. Concrete, which was once recognized only as a structural and functional material, can be transformed into a versatile material through 3D printing technology. In addition, by attaching nozzles to articulated robots and increasing the size of printers, it is possible to overcome the limitations of output shapes and scale.

The automated process of digital design also reduces waste and wastage of temporary materials, such as formwork, and therefore helps to reduce costs. This is one of the reasons why 3D printed architecture can be regarded as a sustainable technology.

Unlike Korea, where a legal framework or mechanism for licensing 3D printed buildings has yet to be established, the United States and Europe have already seen 3D printed housing projects reach commercialization. In addition to the aforementioned housing complex in Texas, a new three-story apartment building in Wallenhausen, Germany, was built using 3D printing technology in 2020. Middle Eastern countries, with their high temperatures and sandy winds, are particularly interested in 3D printing technology that can be used to construct buildings with minimal labor. The government of Dubai has announced that "25 percent of all future buildings will be built with 3D printing technology by 2030," and is working on a project to build the world's first 3D printed mosque.

The global 3D printed construction market is projected to expand from $1.2 billion in 2021 to $3.3 billion by 2031, at a compound annual growth rate of 40.3%*. Of course, there are still challenges to overcome, such as the cost of initial system deployment and the development of construction methods and materials, but the socio-economic benefits of 3D printing are significant and will to bring about a transformative impact on the sector.

*Source: transparency Market Research.

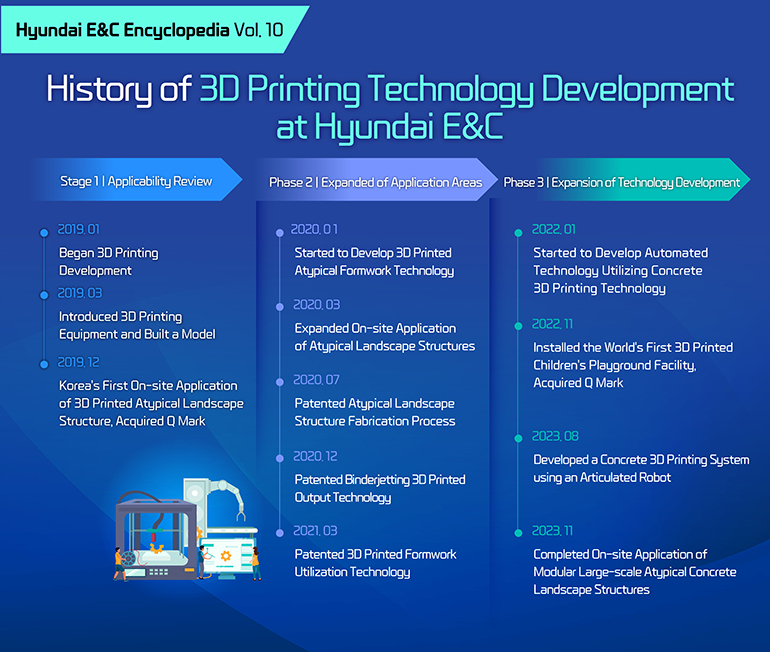

History of Hyundai E&C’s 3D Printing Technology Development

Hyundai E&C, recognizing the emerging trend within the industry, earnestly began to adopt 3D printing technology in 2019. Following the introduction of its proprietary 3D printing equipment and the undertaking of practical research, the company achieved a significant milestone by applying 3D printed atypical landscape structures for the first time in Korea in December 2019. These structures garnered attention not only for their aesthetic appeal but also for their quality, earning the Q mark. This achievement was highlighted as a breakthrough in overcoming the traditional constraints associated with high production costs and the challenges of fabricating various geometries. Hyundai E&C's innovative approach to manufacturing atypical landscape structures was subsequently patented in July 2020,

Hyundai E&C has taken another step forward. In 2020, the company became the first Korean builder to develop a technology that realized an non-uniform formwork by 3D printing large-scale composite plastic. The formwork using 3D printing was evaluated to have improved the production efficiency and competitiveness by minimizing manpower requirements while enabling the manufacture of difficult unconventional geometries. The 2021 patent application for the formwork utilization technology is a testament to its success.

Hyundai E&C's 3D printing technology distinguishes itself through the successful commercialization of a range of in-house developed 3D printed outputs, applying them across various sites. In just the first year following its introduction, Hyundai E&C installed seven unique landscape structures on-site, continuously broadening its range of applications. Among these innovations, a children's play structure was successfully brought to market in 2022, representing a global first in the field. This achievement not only garnered recognition for safety and quality through the acquisition of the Q-mark but also for aesthetic excellence, as evidenced by several prestigious design awards.

In addition, the company has recently secured concrete 3D printing technology using articulated robots, leading the way in construction automation at construction sites. Specifically, the company has a patent pending for a “system for inferring the optimal output combination of concrete 3D printing using artificial intelligence models” that enables automatic control of numerous variables that affect the quality of 3D printed output. The company is also working on developing a construction method that can secure sufficient strength so that it can print tall structures of two stories or higher.

Highlights of Hyundai E&C's 3D Printing Construction Practice

In under five years of research and development in 3D printing technology, Hyundai E&C has made remarkable strides. Beginning with unique landscape structures, the company has progressively broadened its application of this technology to encompass atypical formwork and concrete 3D printing.

① First-ever 3D Printed Atypical Landscape Structures and Playground Facilities

In Hillstate River City and THE H Xi Gaepo, a long red structure stands out against the green grass. These are benches that Hyundai E&C successfully commercialized using 3D printing technology for the first time in Korea. The structure, which offers local residents a place to relax, can be manufactured in a wide variety of colors and forms. It has excellent elasticity and surface finish, and won the Innovation Award at the 2022 Smart Construction Challenge hosted by the Ministry of Land, Infrastructure, and Transport for its technology enabling “Advancement of the Atypical Construction Process Using 3D Printing Technology” and the 2021 Architizer A+ Product Award in the US.

Hyundai E&C has made another “first” by developing the world's first 3D printed children's playground facility. Installed in November 2022 at Hillstate Hongeun Forest, this playground has been acclaimed for its superior aesthetics, achieved by intricately realizing complex functions and geometries beyond mere simple forms and shapes. As it is a facility used by children, it passed all the screening criteria for playground materials, design, and safety, earning the Q-mark for its exceptional performance and quality. Additionally, the “Moon Playground” at “Bucheon Illumistate” stands as a large structure that invites children to engage actively, offering them an imaginative journey to the moon through its integration with the surrounding lights. The utilization of 3D printing technology, which prints products directly from precise three-dimensional coordinates, enabled the company to achieve more than 30% savings in material and labor inputs compared to traditional construction methods, showcasing the efficiency and innovation that 3D printing brings to construction and design.

② Innovation in Work Efficiency, Atypical Formwork Made with 3D Printing

Formwork is a temporary mold into which concrete is poured and set to achieve a specific shape. Hyundai E&C has developed a technology to utilize 3D printed atypical formwork. The patented technology can elaborately create unconventional geometries that are difficult to realize with plywood and steel, which are the main materials for conventional formwork, and can be precisely realized within a machining error of 0.001mm because surface processing can be done simultaneously with printing.

At the entrance of the Hyundai E&C R&D Center in Mabuk, Gyeonggi-do, there is an unconventional small structure standing about 3.8 meters across, 1.8 meters long, and 3 meters high. By utilizing 3D printed formwork, the cost of the structure was saved by about 60 percent compared to conventional steel formwork, and the construction period was also cut in half.

And it doesn't end there. Hyundai E&C has also recently unveiled a plastic formwork that repurposes waste plastic gathered during the research and development process. The “H Wave Bench”, an unconventional curved bench designed for the relaxation of residents at the Illumistate apartment complex in Bucheon, Gyeonggi-do, stands as a testament to this effort. This bench, blending modern technology with plastic wastes, received recognition at the Green Good Design Award 2023, making Hyundai E&C the first Korean construction company to earn this accolade.

③ Automated Construction at Construction Sites, 3D Printing Output System for Multi-Articulated Robot

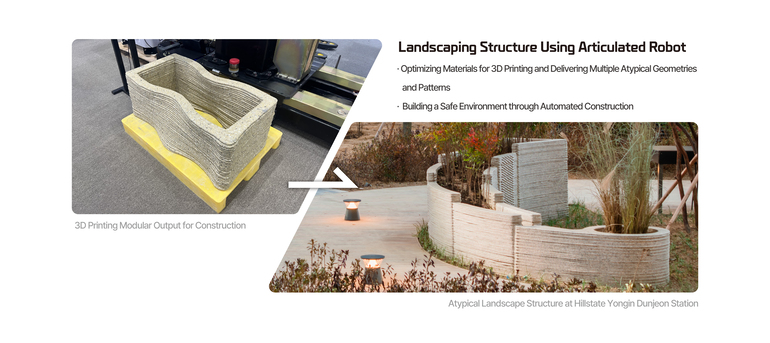

One of the biggest advantages of 3D printing is its ability to utilize a wide variety of materials. Hyundai E&C has succeeded in creating structures using concrete, an important material in architecture. This is demonstrated by the atypical landscape structure planter in the Hillstate Yongin Dunjeon Station. The structure is characterized by the use of a 3D printing system operated by an articulated robot. Having already developed an articulated robot that can replace skilled laborers in 2020, Hyundai E&C has applied it to its concrete 3D printing development system, laying the groundwork for automated construction.

![Articulated Robot Articulated Robot 3D Printing Output System Hose Control Unit [PLC] Pump for Delivering Materials Control Unit (PLC) Articulated Robot Mixer for Blending Materials](/FileContents/EditorImg/20240226/240208_현대건설_뉴스룸_3D프린트건설 최종2_02.jpg)

The system comprises a mixer for material blending, a pump for material delivery, a nozzle for consistent material extrusion, and an articulated robot for precise positional control. Foremost, it aims to address issues like labor shortages at construction sites and enhance safety by substituting robots for human workers. Presently, 3D printing with articulated robots is progressing, enabling the creation of various unconventional geometries and patterns. Hyundai E&C is committed to ongoing research into printing system improvements, materials for reliable layering, and structural engineering techniques to drive automation innovation in construction.

3D printing revolutionizes the transition from one-dimensional blueprints to large, intricate structures, converting waste plastics into stunning artworks swiftly. Dubbed the 21st-century alchemy, its impact spans across various sectors including medicine, science, and art, prompting curiosity about its future advancements. Hyundai E&C is at the forefront of this innovation, pioneering the development of 3D printing technology and establishing a robust system for automated construction. This initiative is set to spearhead a paradigm shift in the construction industry.