Latest News

- Hyundai E&C Accelerates Global Nuclear Expansion into the U.S. Nuclear Market

- Hyundai E&C Shifts into High Gear to Enter Nordic Large-Scale Nuclear Market

- Hyundai E&C Strengthens Korea-Japan Cooperation in Energy Transition and New Growth Businesses

- Hyundai E&C Signals Green Light for Large-Scale Nuclear Power Plant Business in Europe

- Hyundai E&C Unveils Energy-driven Growth Strategy “H-Road”

[Featured Series] Biographies of experts of Hyundai E&C ⑤ BIM Expert Principal Engineer Oh Yeon-ju

BIM Expert Principal Engineer Oh Yeon-ju

Raising efficiency while reducing errors! 'Change catalyst' to bring Smart construction forward

We are no longer in an era where an architecture* with structured design and simplified functions are mainstream. Now, we can easily find buildings consisting of geometric shapes with almost no straight lines and right angles, as if they are art works, and also multi-functional complex buildings. Since architectures are unstructured with many functions, the design plan that should act as the construction guideline has also become more complex. It means that there is a limit to the 2D drawing. BIM (Building Information Modeling) is a digital solution that resolves such a concern in one-go.

*Architectures: This refers to a building constructed on ground or underground and has undergone engineered construction such as architecture or civil engineering.

[Aerial view of National Museum of Qatar created with BIM and BIM model for exterior and steel frame]

BIM is a digital model that allows all information from ‘cradle to grave’ of a building to be stored and managed. It would have been difficult to complete the globally iconic National Museum of Qatar constructed by Hyundai E&C without BIM. This building that was inspired by the ‘desert rose’ fit 76,000 sheets of Fiber Reinforced Concrete (FRC) panels on a circular plate after having established an architecture in the shape of a desert rose with steel frame. It was a task that required very sophisticated technology and it took more than 4 months to complete one flower petal. For the first time in the world, Hyundai E&C adopted BIM in the entire process of construction to build this unstructured building that was unprecedented in the world. The errors in the design drawing could be identified in advance by looking at the three-dimensionally modeled building, and issues that could be generated during the actual construction process could be prevented.

Hyundai E&C adopted BIM at an early stage and additionally attracted professional talents. Also, it established dedicated organizations in each business division, to focus on digitizing the construction industry. Principal Engineer Oh Yeon-ju of the Construction Housing Pre-con team is the core personnel of BIM technology and an expert at Hyundai E&C. Principal Engineer Oh, who received a PhD degree in ‘Design Computing*’ in US is leading the paradigm shift of the construction industry based on professional knowledge.

* Design Computing: It is called ‘Construction IT’ in Korea.

Construction industry is a labor-intensive industry, where digitization was slower than the manufacturing industry. Even while the digital ecosystem evolved from feature phones to smartphones, several tens of drawings for each construction type (discipline) such as civil engineering, construction, equipment and electric works were used to construct buildings. Of course, veteran engineers were on site. However, design drawings varied by discipline, and because the drawings were two-dimensional, there were cases of interferences or mistakes during work.

In 1998, UK government released an interesting report titled, <Rethinking Construction*>. This report that was written to improve quality and efficiency of the construction industry analyzed the reason for slower enhancement of productivity in the construction industry as compared to the manufacturing industry, and pointed to many design and construction errors. This report was sensational across the global construction industry, and it became the foundation for development of digital construction technology such as BIM.

* A report written by John Egan, a renowned management expert of UK, upon request by the UK government. He analyzed why construction industry is falling behind as compared to the manufacturing industry through <Rethinking Construction>.

[ BIM introduced by Autodesk, with the highest market share in the BIM software market. This solution that will bring about innovation to the construction industry enables project performance improvement and saves cost by reducing rework and design errors ]

Now, digital construction technology has become a requirement for efficient operation of projects and high-quality completion. Among different technologies, BIM (Building Information Modeling), in particular, is receiving the spotlight as the base technology that acts as the foundation of digitization of construction. BIM is a digital model that constructs virtual space by integrating data of the entire lifetime of an architecture from planning to design, construction and maintenance. Design is developing gradually from flat 2D CAD to 3D CAD and BIM. 3D CAD may seem similar to BIM in that three-dimensional modeling technology is incorporated to three-dimensionally express a building, but the difference is that only the exterior shape is expressed without relevant information. ‘All information’ required in construction can be ‘comprehensively’ managed using BIM.

Major developed nations such as US and UK are focusing on such strengths of BIM to make it mandatory to use BIM in design and construction in public sectors. National movement to vitalize the use of BIM is also being actively carried out in Korea. Korean government announced the ‘Basic Guideline on BIM for the Construction Industry’ and ‘Construction BIM Vitalization Roadmap’, and it also recommended to apply BIM in all construction industries under the Construction Industry Promotion Act such as civil engineering, architecture, industrial equipment, landscaping and environmental facility. In addition, it is picking up speed to expand the mandatory adoption of BIM in all public constructions by 2030 such as carrying out expansion in a step-wise manner.

Hyundai E&C preemptively carried out pilot application of BIM on site in 2005, which was faster than any other construction company, and in 2015, it completed the construction of the project (new building of LH HQ) applying BIM in the entire processes for the first time in Korea. Construction case of Hyundai E&C was introduced at the International BIM Conference held in US in 2018. Moreover, in 2019, TFT was launched to vitalize BIM, and organizations dedicated to BIM were established in each business division.

Principal Engineer Oh Yeon-ju is a BIM expert of Hyundai E&C. Principal Engineer Oh, who studied architectural engineering in Korea, constructed a database of architectures while conducting ‘BK 21*’ research carried out by the government in 2001. During the process, Principal Engineer Oh became interested in the academic study that integrates computing* technology and architecture, and boarded on to plane to US in 2002. Then, masters and PhD degrees related to design computing (called ‘Construction IT’ in Korea) were obtained at universities located in Pennsylvania and Washington. Principal Engineer Oh, who did not let go of research even while studying, joined the company during the period when Hyundai E&C was securing professional BIM talents to scale out smart construction technology.

*BK 21: An acronym for Brain Korea 21, a program that Ministry of Education led to foster talents who completed masters and PhD degrees.

*Computing: All activities that develop and use computer technology resource from a wide scope.

“I joined Hyundai E&C as a technical engineer in 2015. I could learn real construction that was outside of the textbook in Hyundai E&C. In 2019, after I became of member of BIM TFT, I officially started to contribute to establishing BIM strategy and system by division and securing BIM competitiveness. In the following year, since March, as the head of architecture and residential BIM I started working on establishing the standard to secure objectivity and reliability of BIM data that Hyundai E&C is building. BIM training is also carried out for HQ and site employees. My role is to bring about new change in the construction industry.

BIM that changed the way of working for the construction industry … Enabling detailed project management

Data is the basis for BIM. Integrated information is used to complete design, and size of various materials required for construction, volume, construction order and equipment operation are simulated to enhance the efficiency of construction management. Issues of the plan or design that were difficult to be checked because drawings were separated by discipline can also be identified before starting construction. Through BIM, smooth communication can also be carried out among numerous stakeholders.

“One characteristic is the compatibility with digital technology such as Artificial Intelligence (AI), Internet of Things (IoT) and robot. This is why BIM is called the base technology for digitization of construction. Hyundai E&C carries out virtual construction by incorporating augmented reality (AR) and virtual reality (VR) technology to BIM. We can effectively operate equipment and materials or set hypothetical plans based on this.”

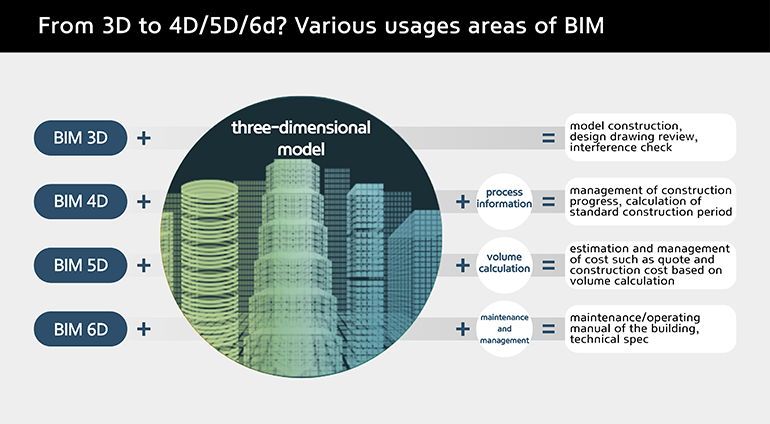

Change that can be achieved in the construction industry with BIM is astonishing. The usage scope of BIM is transcending 3D (three-dimensional modeling) to expand to areas such as 4D (process management, 5D (volume calculation) and 6D (maintenance). BIM 4D allows efficient management of process such as checking the progress of construction against plan by adding process information to three-dimensional models. 5D calculates volume to estimate and analyze cost such as construction cost, and 6D is used in managing and maintaining architectures through data input such as operating manual and maintenance cycle.

“Hyundai E&C has many experiences in execution from 3D to 6D. As an example, Daegu National Information Resources Service that completed construction last year, applied myriads of digital construction technology as an innovative smart construction site of Hyundai E&C. BIM encompassed 6D including Virtual Design and Construction (VDC)* technology. As a result, Hyundai E&C received the grand prize (Minister of Land, Infrastructure, and Transport Award) in the architecture category at the ‘BIM Awards 2021’, the largest BIM contest in Korea. It was the second award after having received the grand prize for civil engineering with the BIM case of Godeok Bridge (tentative) in Section 14 Sejong-Pocheon area in 2017.”

*Virtual Design and Construction: Refers to planning all perspectives of project through a digital method including scheduling, cost prediction, risk management and so forth using 3D BIM model and other information.

From 2020 until now, Hyundai E&C applied BIM to much more than 70 domestic and overseas construction projects. BIM was critical in successfully constructing architectures with unique structures such as the new building of Amorepacific designed by David Chipperfield and National Museum of Qatar designed by the world-renowned architect, Jean Nouvel.

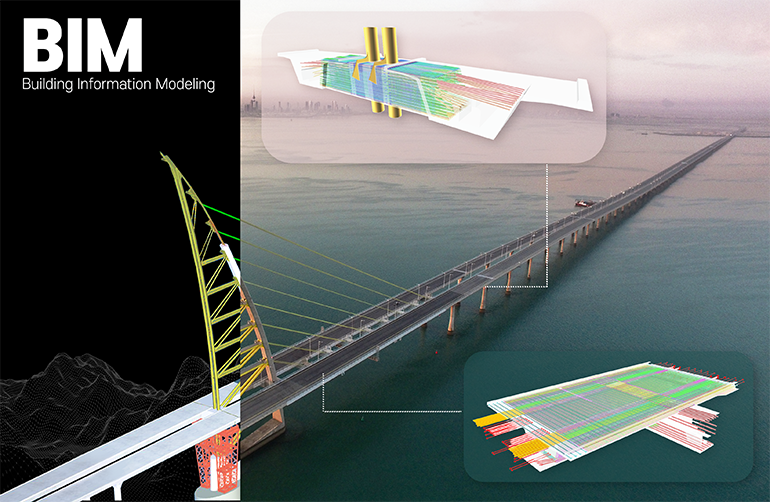

[ Seikh Jaber Al Ahmad Al Sabah Maritime Causeway in Kuwait that is 36.1km in total length, which connects the capital city of Kuawait, Kuwait City and Subiya region. Hyundai E&C applied BIM technology for the construction of an asymmetrical cable-stayed bridge that is very difficult to construct in the shape of a sailboat ]

BIM is also applied in civil engineering projects such as bridges and tunnels. For Seikh Jaber Al Ahmad Al Sabah Maritime Causeway in Kuwait, the construction period was pulled in by a year and a half as compared to the original plan by applying BIM in the planning and the design stage. BIM was adopted in the entire construction process for the first time among domestic expressway projects in Section 14 of Sejong-Pocheon Expressway (Anseong-Guri) that is expected to be completed next year. Information for the entire process of construction is being stored in BIM through Digital Twin. * Such technical capability and execution experience led to the winning of the order for Expressway No. 47 Namyangju-Wangsuk relocation (underground development) construction, the largest technology tender project in the area of civil engineering. This project will be combining the construction knowhow for underground space carried out by Hyundai E&C until now with smart construction technology including BIM.

*Digital Twin: Technology where reality and the virtual world are synchronized in real-time to reflect the same data.

공사 조감도_770.jpg)

[ Hyundai E&C won order for ‘Expressway No. 47 Namyangju-Wangsuk relocation (underground development) construction’, the largest technology tender project in the area of civil engineering, to once again prove the best-in-class technical capability that encompasses design and construction. Hyundai E&C proposed a three-dimensional underground road that separates the top and the bottom for the first time in Korea, and is planning to implement various digital construction technology such as BIM to realize the above ]

Hyundai E&C is sparing no expense to secure the best-in-class technical capability by adopting BIM that is customized to the site to be ahead of the needs of the clients. Such efforts led to the certification of the international standard for BIM, ‘ISO 19650:2018(hereinafter ISO 19650)’, from British Standards Institution (BSI) in July 2022. ISO 19650 can only be obtained after having passed strict validation and judgement that is in line with the global standard such as internal BIM guideline and process, interview of the working-level and executives, performance of executed projects and so forth. Principal Engineer Oh Yeon-ju contributed greatly in the obtaining of the international standard certification by carrying out activities such as establishing process and standard for BIM.

“Last year, ISO 19650 certification was obtained in construction and civil engineering, and this July, the certification was obtained in all areas including plant. We were able to achieve good results thanks to Hyundai E&C’s effort to set BIM strategy centering on dedicated organizations and constructing BIM process and providing technology support to execute and win orders.”

[ Principal Engineer Oh Yeon-ju, who is checking the integrated model through the cloud-based BIM cooperation system adopted by Hyundai E&C ]

Hyundai E&C is doing its utmost so that BIM can stably settle in at the construction sites. Principal Engineer Oh Yeon-ju emphasized, “We have to change the way of working with BIM for everyone who participate in construction, and not just for some experts”. For this, large and small-scale experiences and success cases should be accumulated. This is why Hyundai E&C preemptively invests in digital construction technology including BIM.