Latest News

- Hyundai E&C Becomes Key Player in the Nuclear Decommissioning Market

- Hyundai E&C Accelerates Global Nuclear Expansion into the U.S. Nuclear Market

- Hyundai E&C Shifts into High Gear to Enter Nordic Large-Scale Nuclear Market

- Hyundai E&C Strengthens Korea-Japan Cooperation in Energy Transition and New Growth Businesses

- Hyundai E&C Signals Green Light for Large-Scale Nuclear Power Plant Business in Europe

Broadly Benefiting the World with Amazing Technology!

The world develops little by little thanks to someone’s concern and efforts without us even knowing. Hyundai E&C is also one of these ‘someone’! By shaping the most comfortable houses, land we step on every day, and construction sites that create a living space, Hyundai E&C is focusing on research and development to create a better world, building a space that is essential for everyone’s lives. Making customers happy, environment healthy, and site safe! Hyundai E&C’s technology that benefits the world is just amazing!

Bringing Comfort to You and Your Neighbors:

Leading Korea’s Grade 1 Inter-floor Noise Reduction Technology.

‘Inter-floor noise’ scourge has been making news headline for a long time. Downstairs who can't sleep at the sound of a foot thumping upstairs, and the upstairs neighbor is worried that the interphone will ring any moment because of noise. You try placing a living room mat or wearing slippers, but with the never-stopping noise, the suffering goes on both for the upstairs and downstairs households

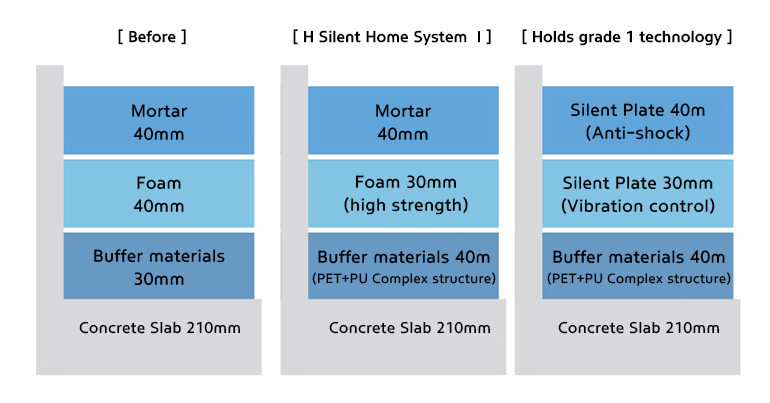

Now, there is no need to worry about theses problems in apartments built by Hyundai E&C. This is because it has secured the grade 1 performance technology, which is the highest level of inter-floor noise blocking for the first time in Korea. The H Silent Home System Ⅰ's highly functional buffer material, which was introduced in May, has been upgraded to control the ‘shock-specific frequency’ by applying materials specialized in ‘shock control’ and ‘vibration suppression.’ With the principle that ondol layers, which have a much higher density and intensity than before, absorb noise between floors effectively, the Korea Conformity Laboratories (KCL), a state-approved testing agency, officially confirmed the grade 1 performance of 39 dB (decibel) of Hyundai E&C’s technology.

The noise between floors is divided into light and hard weight impact sound such as the sound of dropping a golf ball and of dragging a table chair and powerful and heavy weight impact sound such as the sound of children running and adults' footsteps. The main cause of conflict among households is low frequency weight impact sound. Hyundai E&C’s weight impact sound blocking grade 1 of 39dB is far below the statutory standard of grade 4 of 50dB and attests to excellent performance making it difficult for lower floor apartments to perceive excessive impact sound coming from upstairs.

This achievement is especially meaningful as it was confirmed through on-site demonstration. Usually, inter-floor noise tests are conducted in a laboratory with a Bang Machine that smashes tires on the ground to simulate impact sound. However, this test is meaningful in that it was obtained by making the special floor structure directly at the site and evaluating the noise from the upper floor from downstairs under similar conditions to the actual living space.

Hyundai E&C continues to conduct studies to create a happy residential environment for customers. The latest technology, adding the know-how of the past decade, is also the result of the hard of work experts in various fields such as noise/vibration, structure, and materials. In addition to relieving concerns over noise between floors, Hyundai E&C plans to give its best until it can build apartments where children can freely run around and play inside.

[ Variations of floor structure to reduce inter-floor noise ]

[ On-site Demonstration Test for Inter-floor Noise Reduction Technology ]

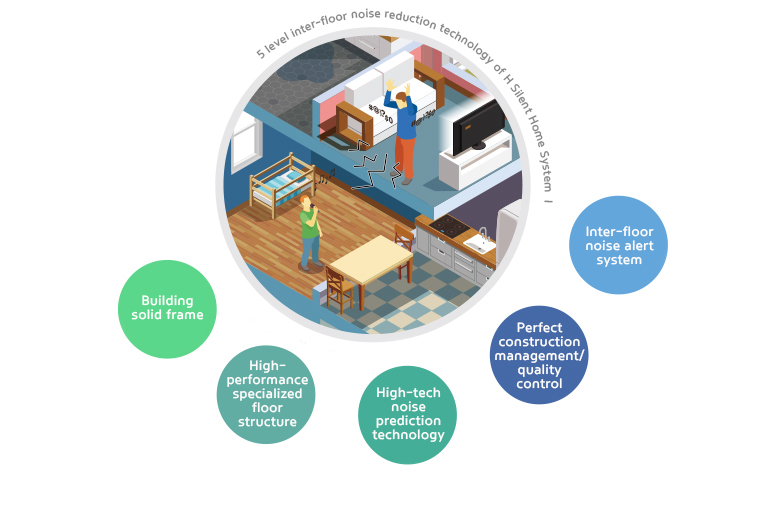

[ 5 level inter-floor noise reduction technology of H Silent Home System Ⅰ ]

IPTD, dioxin-contaminated soil purification method for a sustainable living environment.

Healthy land is the first and foremost element for best construction, happy life, and even sustainable human environment. Hyundai E&C is actively taking the lead in restoring the polluted environment by focusing on research and development of soil purification technology and internalization of advanced technologies. So far, three new environmental technology certifications and 25 domestic and foreign patents, including technology to wash with water or remove heavy metals from the soil with wind, have been registered. Korea’s top builder is also collaborating with leading overseas companies to carry out projects with speed and accuracy.

Currently, Hyundai E&C is purifying dioxin-contaminated soil of about 11,031㎥ at the camp market site. As it is the first large-scale dioxin-contaminated soil purification project in Korea, the company is collaborating with overseas technology partner whose technology has been validated through purification of Da Nang Airport in Vietnam. The technology introduced to safely and effectively remove dioxin, a first-class carcinogen, is In-Pile Thermal Desorption (IPTD) method. Substances that cannot be extracted by heat, such as heavy metals, are purified as if washing with soil and detergent in a huge washing machine, but heating approach is efficient when removing contaminants that can be gasified.

The IPTD heat treatment method is a technology that burns and eliminate harmfulness of the extracted dioxin gas by applying heat to contaminated soil. When heating rods, steam extraction pipes, and air injection pipes are horizontally installed in a pile of contaminated soil and the soil temperature is maintained at 335 degrees or higher, the dioxin in soil is separated in vaporized form. If the extracted steam is gain burned at 1000 degrees or higher in a thermal oxidation facility to completely oxidize dioxin, only zero-harmful gases can be emitted. The results of the demonstration experiment conducted at the camp market site in 2019 showed that the dioxin concentration, exceeding min. 247 to max.11,468pg-TEQ/g (1 trillionth of a gram) decreased to min. 0.9 to max. 9.7pg-TEQ/g after purification. This is far below the European requirement of 100pg-TEQ/g for infant playgrounds and the Swedish standard of 20pg-TEQ/g for residential areas.

All of these purification processes are carried out in enclosed facilities built with negative pressure equipment. The move is aimed at minimizing heat loss due to the nature of the construction method, which is important to maintain high temperature, as well as prevent scattering dust, noise, and gas from spreading to nearby apartment complexes or schools.

Hyundai E&C, which has world-class soil purification source technology, will continue to make efforts to pioneer wider and healthier land beyond Korea.

Big data for Safe Site Management:

Disaster risk prediction, process delay prediction, and CS analysis system for apartment houses.

In the past, intuition and experience of workers used to be the most important means of decision-making at construction sites. Now, problems can be prevented and solved more efficiently through objective evidence based on big data. The construction experience of Hyundai E&C, as profound and rich as its long history, is the company’s biggest asset. It is increasing safety and productivity efficiency by putting together this vast amount of past data and utilizing data processed, analyzed, and derived in accordance with standards in various ways.

Currently, Hyundai E&C is using big data and AI technologies in three main applications. The first is 'disaster risk prediction'. Based on about 39 million data accumulated by carrying out various construction projects over the past decade, high-risk operations are intensively managed to prevent accidents. AI learns situations in which disasters could have or actually occurred in the past and provides disaster probability information for each type of construction/accident/site. Quantified disaster probability information and safety management guidelines are delivered to site managers by e-mail and mobile on the day of work, allowing them to focus on safety management.

Second is 'process management' at apartment complex sites. AI collects and analyzes about 700,000 cases of process data at the site in the past to learn the cause of the construction delay, and based on this, it informs the current site's ‘expected progress rate in three months’ and ‘reasons and countermeasures for delay’ of similar sites. At sites where the construction is expected to be delayed, pre-alerts are sent out to help prepare measures in advance and meet the deadline.

Finally, big data and AI technologies are also being applied to establishing a ‘CS analysis system for apartment houses’. Based on about 8 million complaints data dispersed across a number of systems, the cause and occurrence of defects by site/construction type are analyzed to continuously derive measures to minimize complaints. In addition, it is striving to minimize the number of cases and cost of solving defects and improving customer satisfaction and brand value by establishing a ‘negative language dictionary’ based on the complaints received at customer centers to quantify defect frequency.

Since Hyundai E&C established an organization dedicated to big data in 2018, it has expanded the scope of big data and AI technology applications through various research and pilot projects. Since last year, it has been validating their effectiveness in site management practice across construction process, quality and safety and plans to establish a company-wide data-based decision-making system by 2023.