Latest News

- Hyundai E&C Accelerates Global Nuclear Expansion into the U.S. Nuclear Market

- Hyundai E&C Shifts into High Gear to Enter Nordic Large-Scale Nuclear Market

- Hyundai E&C Strengthens Korea-Japan Cooperation in Energy Transition and New Growth Businesses

- Hyundai E&C Signals Green Light for Large-Scale Nuclear Power Plant Business in Europe

- Hyundai E&C Unveils Energy-driven Growth Strategy “H-Road”

Hyundai E&C’s top safety and quality management technology

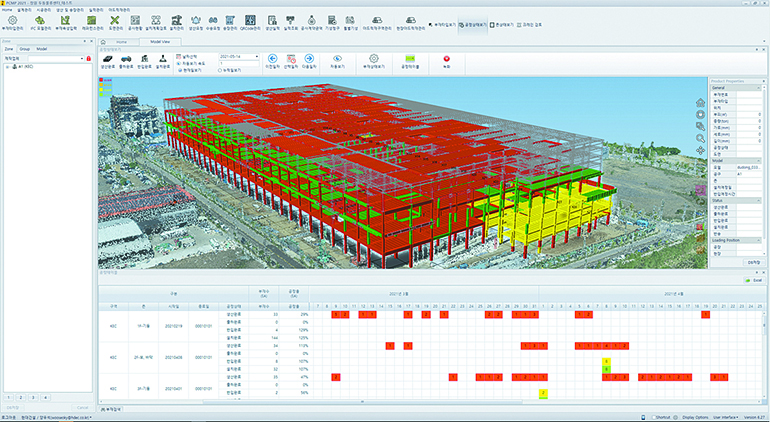

¹ SCMP(Smart Construction Management Platform)

SCMP is a platform that can monitor all stages of “design-production-manufacturing-import” of major construction materials in real-time using BIM. It is expected that operation of more complex sites requiring large-scale materials such as steel frames, PCs, and curtain walls will become more accurate and easier as material status can be managed in real time using mobile devices such as smartphones and tablet PCs. The SCMP is being developed in 1 to 3 stages. The first stage, which was developed early last year and completed on-site application, is specialized in PC construction management. The second phase, which is under development this year, focuses on “Steel-Frame Construction Material Management”, and the third phase will be developed in the future.

² Q-Pocket

Q-Pocket is the industry’s first smart integrated inspection system that enables real-time on-site quality management using mobile and web. It has established a Unact(contract-free) and Paperless system across all construction quality management operations, by using “online payment system and automatic notification”, moving away from the existing “on-site quality check-move to office-report preparation-face-to-face approval” process. Q-Pocket, which is being used at all Hyundai E&C sites, allows for an integrated quality management from establishing inspection plans, framing and finishing works, and subsequent defect management. In particular, the defect management system within the Q-Pocket - which can identify and check the status of subcontractors by construction type in real time and automatically notify inspections – is patented.

³ HIoS(Hyundai IoT Safety System)

HIoS is Hyundai E&C’s safety management system, developed for the first time in the industry in 2019 and is a smart safety platform that is familiar to all Hyundai E&C field employees. To the existing features of ▲ worker location control ▲ closed space gas leakage detection ▲ tower crane collision prevention and ▲ environmental complaints management, the following have been added to the upgraded “Vision 2.0”: ▲ worker infection control ▲ flood response and ▲ fire response system. Hyundai E&C plans to prevent safety accidents and increase work productivity by detecting on-site anomalies of workers' health and on-site conditions in advance through HIoS.

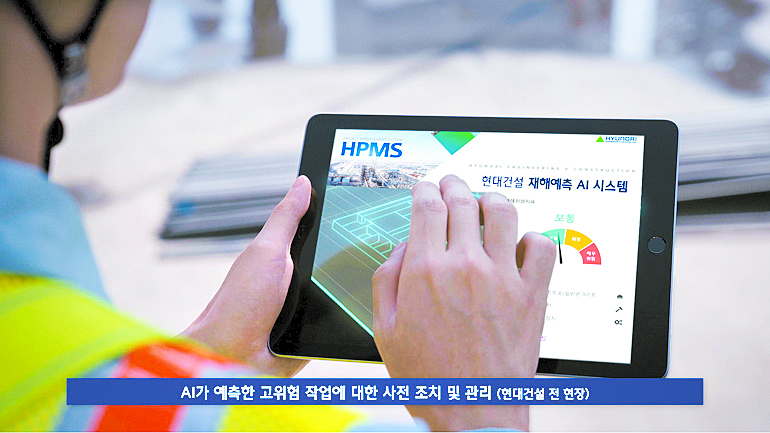

⁴ Disaster Prevention AI

Hyundai E&C started AI-based safety management in October last year. Disaster Prediction AI is a system that provides disaster risk information of Hyundai E&C’s domestic projects to each site on a daily basis. This system was has been developed by Hyundai E&C after collecting more than 39 million big data in various projects carried out over the past decade. Disaster Prediction AI analyzes the scheduled construction information entered into the site management system by the field manager to derive the probability of safety accidents and safety management guidelines by type. Hyundai E&C will continue to digitize safety-related information collected at each site to enhance the performance of AI in disaster prediction and use it in areas that require safety disaster prevention.

Written by Park, Hyunhee