Latest News

- Hyundai E&C Shifts into High Gear to Enter Nordic Large-Scale Nuclear Market

- Hyundai E&C Strengthens Korea-Japan Cooperation in Energy Transition and New Growth Businesses

- Hyundai E&C Signals Green Light for Large-Scale Nuclear Power Plant Business in Europe

- Hyundai E&C Unveils Energy-driven Growth Strategy “H-Road”

- Hyundai E&C to Build First Unit of SMR-300, a Model for U.S.-Korea Energy Cooperation

Pioneer in Singapore’s Land Efficiency Policy: Labrador, Southeast Asia`s Largest Underground Substation

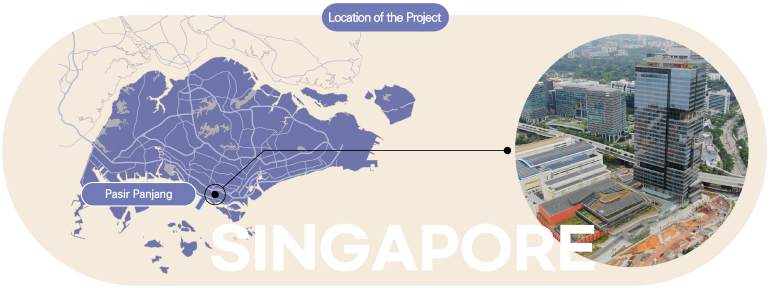

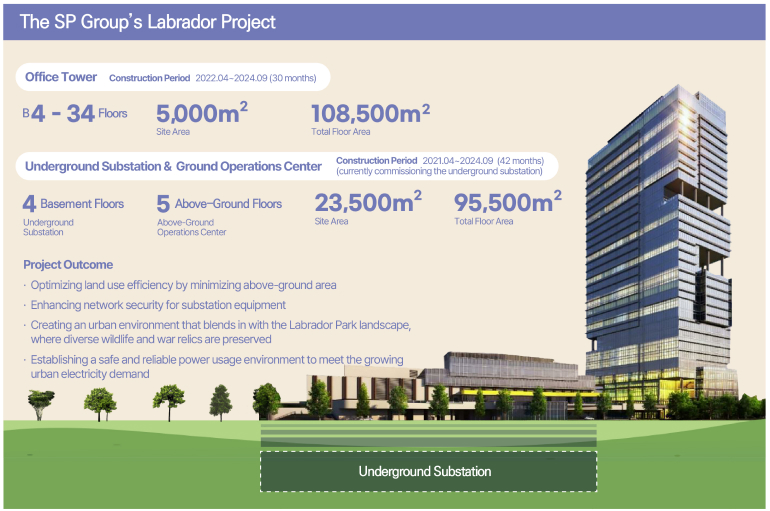

The greatest proof of human achievement is construction. Hyundai E&C is a prime example, expanding Singapore’s land area by 7% through land reclamation from the sea. Now, Hyundai E&C is undertaking yet another landmark project in Singapore: building the country’s first underground substation, part of a new land efficiency initiative. This ambitious project spans an area equivalent to four football fields (around 30,000㎡) with a total construction cost of approximately $390 million, with Hyundai E&C at its core.

Becoming a Partner in Singapore’s First Land Efficiency Project

Singapore is a dynamic hub where global construction companies compete to showcase their advanced construction technologies. Hyundai E&C has built a strong presence in Singapore by constructing numerous landmarks, including Asia Square Tower, Marina One, South Beach Tower, and Suntec City. Winning the bid for the Singapore Power Group (SP Group)’s Labrador project in 2021 is a notable achievement that highlights Hyundai E&C’s unrivalled competitiveness and capabilities.

.jpg)

Pushing the Boundaries of Underground Space with Technology

Construction sites are like living organisms. They are constantly changing, and you never know what might happen, especially underground. Building an underground substation begins with understanding what lies beneath the surface. The more complex the geology, the greater the challenges the site presents.

The Labrador site sits at the intersection of two geological zones with distinct characteristics, adding to the project’s complexity. Where geological zones meet, the rock formations are typically faulted, making them more fragile and unstable than a single, solid foundation.

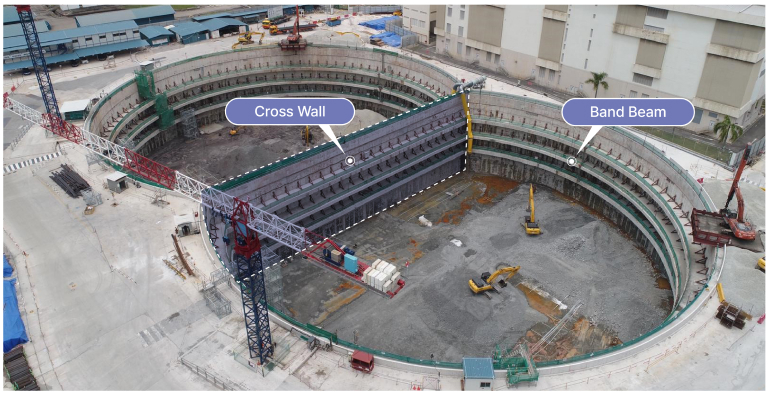

To prevent soil collapse, Hyundai E&C employed the Slurry Wall* method, known for its high strength and water resistance, constructing it as two coffer-dams*, each roughly the size of two football fields. The Slurry Wall technique involves injecting a stabilizing solution(bentonite) into the excavation site to prevent collapse and form a reinforced concrete wall. Hyundai E&C took meticulous care to maintain a consistent concentration of bentonite, free of floaters, to ensure deep and steady excavation underground.

*Slurry Wall: A construction technique that installs a continuous reinforced concrete wall underground. A stabilizing solution (bentonite) is applied simultaneously with excavation to prevent the walls from collapsing and to block groundwater inflow.

*Coffer-Dam: A structure in which partition walls are installed between bulkheads to divide the area into compartments.

[ The Labrador site uses slurry wall construction in the form of a coffer-dam. To maximize interior space in the basement, there are no “beams” supporting the slab weight on the columns. Instead, a cross wall and circular border beam were temporarily installed between two circular structures to bear the earth pressure during construction ]

Building an underground substation in a densely populated city center with a complex network of facilities was no easy feat. The city’s layers of underground service lines made construction a risky endeavor, and the Labrador site was no exception. Situated near an existing above-ground substation and surrounded by subway stations, tunnels, and overpasses, the site posed unique challenges. Hyundai E&C conducted over 100 surveys to locate buried objects and collaborated closely with relevant agencies throughout the construction period, successfully removing numerous underground obstructions and rerouting drainage channels.

Coordination with various related companies was essential, as the metal platform supporting OEM equipment, numerous cables, and various facilities had to be constructed in a confined underground space with absolute precision. The cable support process was particularly critical, requiring the design and installation of support structures to ensure the cables remained stable and secure. With over 11,000 cables interwoven like a spider’s web and resembling a roller coaster, Hyundai E&C leveraged its experience in hospital construction* to precisely engineer the cable placement angles using BIM (Building Information Modeling). By handling the design itself, Hyundai E&C achieved more efficient collaboration with the client's OEMs and took a leading role in designing and deploying the management platform alongside the client, who will operate the substation in the future.

*In the case of hospital construction, not only the functional arrangement of each room, but also each facility required for the hospital and building are elaborately and sequentially constructed through coordination. In the case of underground substations, the coordination experience of hospital construction is crucial because the necessary facilities such as OEM equipment and various cables must be constructed without error in a limited space.

[ Hyundai E&C utilized BIM to fine-tune the design and layout of underground substation piping, cables, and other facilities ]

Prioritizing Safety as the #1 Factor in Power Infrastructure

Behind the development of technology, there must always be a strong backbone of "safety". Substations that handle power infrastructure are considered nationally critical facilities, and the requirements for counterterrorism and security are reflected in their design.

[ Labrador underground substation and office tower with various blast-resistant methods to deal with power infrastructure ]

From the early stages of construction, the Labrador site underwent a rigorous inspection process by Singapore’s Ministry of Home Affairs (MHA). To protect the underground substation from potential terrorist threats, Hyundai E&C installed a 2-meter Transfer Slab* between the substation and the first-floor slab. For the ground operations center, it also reinforced durability by encasing the columns in steel jackets.

The office tower constructed right next to the substation was also built with blast-resistant features using the CFT (Concrete Filled Tube) method. Typically, concrete is poured around a steel column, but with the CFT method, concrete is filled inside a steel tube to increase durability and maximize external blast resistance. This method is not commonly used in Singapore, where construction expertise and workforce for such methods are limited. However, Hyundai E&C, drawing on its extensive experience in building bridges and infrastructure, applied the CFT method to ensure the building could effectively absorb impact energy.

* Transfer Slab: A horizontal structural member that connects the lower and upper structure of a building. It is usually made of thick, high-strength reinforced concrete and is designed to withstand large loads.

Of course, these specialized environments aren't the only places where “safety” comes into play. The Labrador site’s achievement of 10 million accident-free hours in February, despite a daily workforce of over 1,600, is a testament to Hyundai E&C’s commitment to rigorous site management. A key part of this success is the Project Safety Review (PSR) system implemented on-site. Before the main construction began, Hyundai E&C conducted two comprehensive reviews of construction details and safety requirements for each work type with the client and consultants. During construction, an AI-powered CCTV system was used to detect safety non-compliant issues in real time, instantly alerting responsible personnel. Through these meticulous and proactive measures, safety is continuously reinforced.

[ AI CCTV checks the safety risk of field workers and notifies safety managers of their location and hazards in real time ]

Transformation in Construction: Integrating Smart Energy-Saving Technologies

The construction sector is also embracing smart energy efficiency technologies to ensure the sustainability of the industry and set the stage for future growth. The Labrador project is another example of incorporating smart energy-saving technologies, with a temperature control system using AI and IoT to improve energy efficiency compared to the existing air conditioning system. A four-story underground heat storage tank will also be constructed to utilize water from the reservoir that is cooled at night to cool the building during the day. This virtuous cycle system is expected to achieve Green Mark Platinum Super-Low Energy certification from the Singapore's Building and Construction Authority (BCA).

Promising a Milestone in Advanced Technology for the Near Future

With its limited land mass, Singapore is continually pursuing projects to relocate urban noxious facilities underground and upgrade existing subterranean infrastructure. The upcoming wave of underground substation projects similar to the Labrador project reflects the strong interest and high expectations from the local government.

Hyundai E&C’s experience in constructing underground substations positions it with a distinct advantage for future redevelopment projects in Singapore. Leading the way in Singapore’s transformation, Hyundai E&C is riding the first wave with elegance and confidence. Why not ride the second wave as well? We look forward to Hyundai E&C’s unending “Dream Road” in the near future, beginning with Singapore’s Labrador project, a groundbreaking milestone in advanced technology.

[ On-site Employee Group Photo ]